Comparing of Rotary Screw Air Compressor vs Reciprocating Air Compressor

Do you have any idea about these two standard air compressors? Yup, that is a Rotary screw air compressor and Piston or reciprocating air compressor. In this blog, we will show the comparison and performance of the Rotary screw air compressor and Reciprocating air compressors.

Everyone in the business field has this major question in their mind Should I buy a Reciprocating or a Rotary screw? Mutually both of the compressors create compressed air but it depends upon the application so we will explain it briefly.

What Is the Dissimilarity between the Reciprocating Air Compressor and Rotary Screw?

Both of the compressors produce compressed air utilizing positive displacement, These compressors compress air mechanically to reduce its volume but the mechanics or engine is different.

Reciprocating Air Compressor

This air compressor is also known as a piston air compressor.

Pistons were used in the mid-1600s, Now these are largely used in industry, and Similarly, the same compressor was used during the 1800s

The reciprocating air compressor engines are systematic and easy to maintain. They are adequate for applications.

Rotary Screw Air Compressor

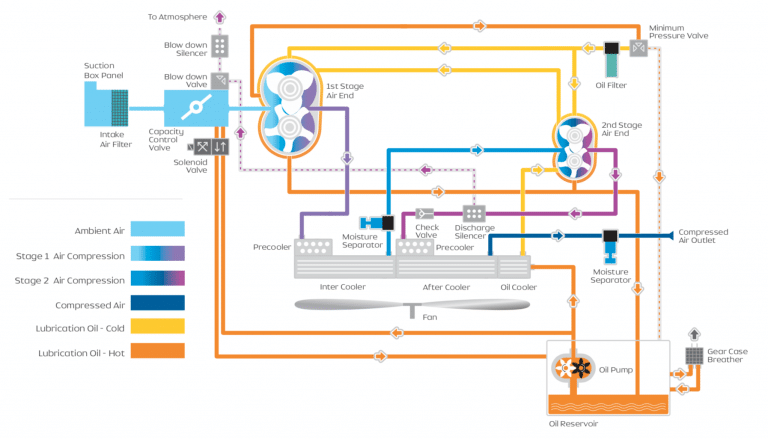

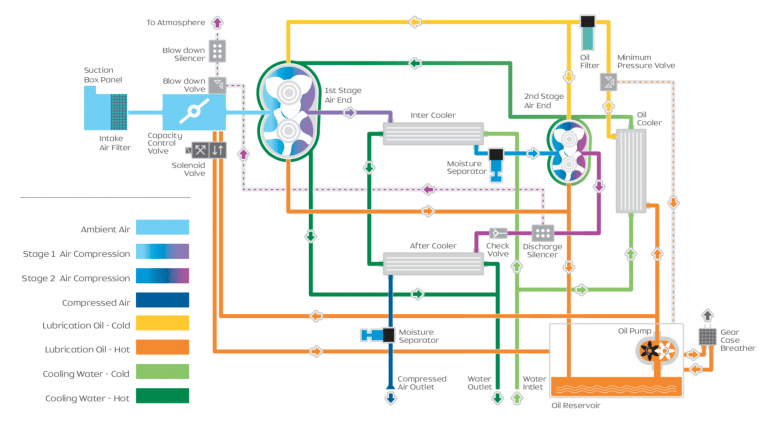

Rotary screw air compressors have been about since the mid-1900s. There are two rotors and a compressed air system present in the Rotary screw air compressor.

The air is pulled into the chamber and squeezed into a smaller space. The rotors turn and are continuously compressed in this process. There are a few moving parts in the rotary screw air compressor and mainly this air compressor is more reliable.

Which Is the Best Reciprocating Compressor or Rotary Compressor?

Reciprocating or Rotary doesn’t matter and it’s all depending upon how the compress is used? How much compressed you need and the environment is also part of it.

Mainly you want to know about the pros and cons of Reciprocating or Rotary compressor

Reciprocating Air Compressor & Rotary Air Compressor

Pros of Reciprocating Pros

- High trustworthiness

- Silent function

- 80-99°F Cooler interior working temperature

Pros of Rotary

- More extended life

- Easy maintenance

- Low initial money investment

- Can be run in sheltered outdoor or polluted circumstances

Cons of Reciprocating

- Loud and noisy level up to 100 DB

- high temperature and hot up to 150- 200 F

Cons of Rotary

- Lower CMF

- Periodic use (20-30% duty cycle)

Both have pros and as well as cons so it depends upon the situation and also depends upon your application

When to Use a Reciprocating?

This is the type of air compressor which is best for when the air is worked intermittently by using short bursts. The reciprocating air compressor is the best little machine shop, building sites, and other small companies. This compressor is to run blow off and cleaning, sandblasting, airbrushing, Check Tire Pressure.

There is one main advantage of this air compressor is when the compressor is running continuously or at maximum capacity, it will not be damaged.

It’s being sized by 50% higher than the actual CFM to let the compressor avoid excessive heat from the motor.

When to Use a Rotary?

A rotary screw air compressor is best for heavy-duty work and continuous air and it is otherwise called a heavy-duty air compressor. These are the pillars of industry, big construction, and road construction work. It is designed to produce continuous air and flow of consistent air.

Mainly the air produced by the rotary is cleaner than the reciprocating and mostly it is the best choice for paint tubes and packaging.

Rotary screw compressors can work under extreme conditions like high temperature or lower temperature the machines can work in urban-rural areas.

They are designed to have more power and extremely high tools and are easier to maintain. The rotary screw air compressor has 70% fewer parts and it turns lower maintenance.

Buying the air compressor is good but want to choose the best air compressor and Air compressor dealers.