In short, An compressor is a pneumatic device that converts power by using an electricity, diesel, or gasoline engine into a pressurized air called a compressor. This two have the biggest competition gas and air compressor.

Next step everyone had this question: Which is the best?Gas compressor or air compressor? Which compressor to choose and which is right for business?

Oh! it’s getting complicated, let’s dig it out. A gas or air. Which compressor is gonna win? let’s see & read with consciousness.

Benefits of Gas Compressor

Natural gas compressor: Everyone can know about this but also you want to know about CNG compressor and RNG Compressor.

So What are CNG and RNG? Do you have any ideas? Ok! CNG is nothing but compressed natural gas. RNG is renewable natural gas. To be simple taking biogas and moving compressed natural gas into a grid or providing a fuel station for natural gas vehicles defining the

CNG and RNG are at their best outdoors in remote areas and they can provide regular pressure, long-lasting compression, and strong power. The natural gas compressor is a wide range of strong compressors by using natural gases like biomethane, etc. Without no need to plug the power source it has more mobility so can place the compressor in the best location and is unrestricted by other access elements. It can maintain its most powerful efficiency level while running at as low as a 30% full load.

Benefits of Air Compressor

Before talking about air compressors, I want to explain that air is a useful tool.

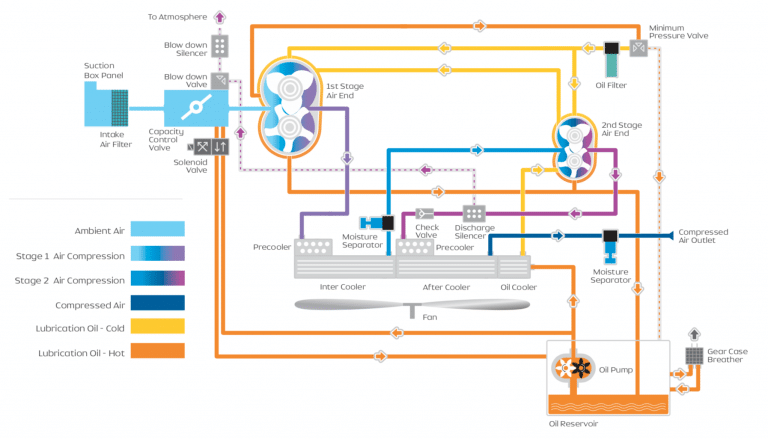

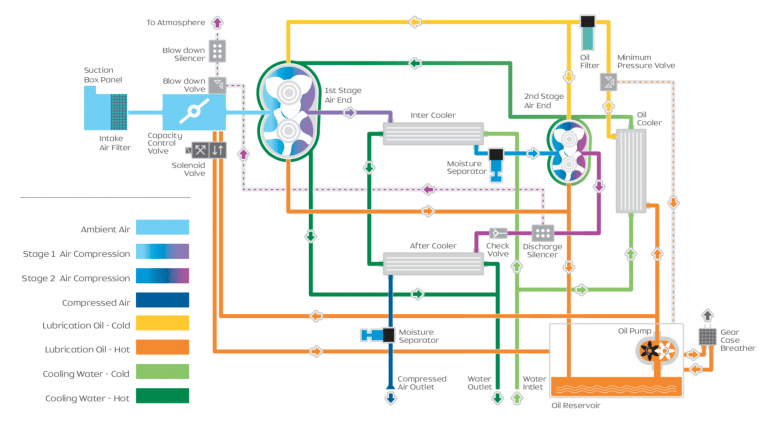

This pneumatic device can have many different accessories, making it multiple tools. It is also a small and quiet tool and has many types like a Piston, oil-free air compressor, portable air compressor, Reciprocating and Rotary air compressor, etc.

It is lightweight and will comfortably fit in any space.

The portable is significantly less noisy than a gas.

Pros and Cons.

Gas Compressor Cons

The first cons of the natural gas compressor are it can produce highly dangerous gas. All gas compressor types are at risk indoors.

Natural gas compressors like CNG and RNG-type air compressors have lower life maintenance. Gas compressors have a high risk of fire accidents. The gas compressor is very loud and the level of noise can affect your employees.

Gas Compressor Pros

A gas compressor is typically good and it performs outdoors.

It tends to be more expensive and seems to be the biggest drawback when you buy a gas compressor.

Air Compressor Pros

Air compressors have an individual advantage because they can operate in any situation. It runs smoothly and quietly. Air compressors can work continuously and work best in industries.

It is less expensive and adding an air compressor with air filters, water filters are easier. Usually, it is more powerful and has a higher air capacity (CFM output).

Air Compressor Cons

If the air filter doesn’t change regularly it will end at risk.

Maintenance of air accessories is important.

Gas vs Air: Let See Who Wins?

In the end, air compressors are much better than gas. So investing money in an air compressor is best and also less expensive compared to a gas compressor when you buy a compressor for business or industry. We suggest Elgi is the right option. For more information ask experts.