A Diesel generator is processing the electric generator to generate electrical energy. This is the specific case of the engine generator. A diesel compression-ignition engine often is designed to run fuel oil also some types are adapted to run with liquid fuels or natural gas.

Generator Users require less maintenance due to their durability (it means measures the length of product life), reliability (it means the product will not fail within a specific period of time), and the sturdiness characteristic (It means the durability of the product), and also they are considered cheaper to operate due to the low fuels costs as compared to the other types of fuels such as gasoline and propane. When you reach the best generator dealers they’ll guide you.

Diesel Generator

Every Business needs a Standby Diesel generator For Backup Power and the Generator Gives More power to the whole Unit. Also considered to withstand heavy loads for long hours and start off the power supply on the full load within minutes and must be regularly maintained to ensure they provide quality power throughout their service life.

The best diesel generator maintenance practice is following the maintenance schedule provided by the generator manufacturer to ensure maximum service time for the generator and proper operation when it is called upon to provide power.

The engine is the core component of the generator. If you want to run your generator well without any mechanical issues or electrical issues must maintain the generators carefully.

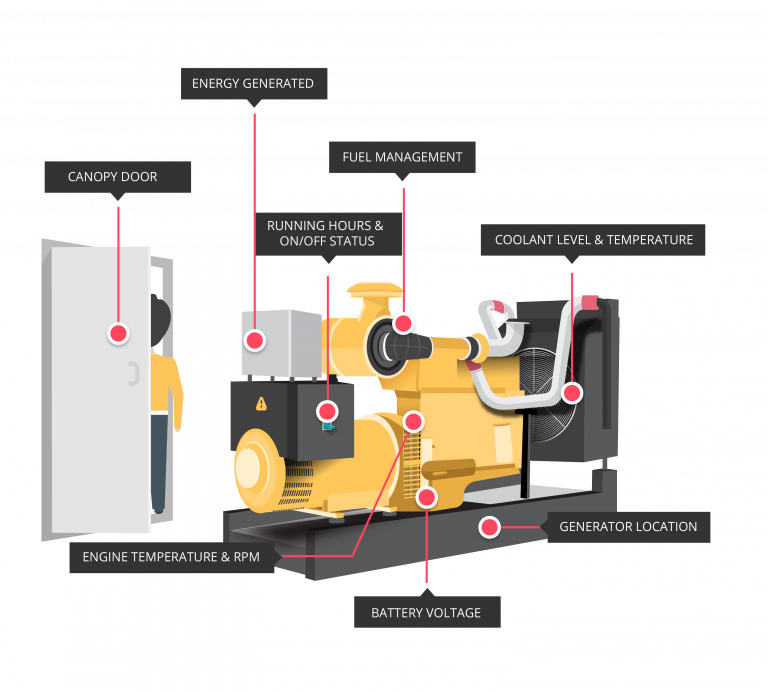

Once you start running the diesel generator, the exhaust system, fuel system, DC electrical system, and engine require close monitoring for any leaks that can cause hazardous occurrences. The very essential one is to maintain the internal combustion engine. A backup generator is mandatory in the industry and also proper maintenance of diesel generators is important so take a look at these steps.

Step 1: Lubrication Service

The Engine oil must be checked while powering off the generator at regular intervals using a dipstick.

Allow the oil in the upper portion of the engine to drain back into the crankcase and follow the engine manufacturer’s recommendations for API oil classification and oil viscosity.

Keep watching the oil level as near as possible to the full mark on the dipstick by adding the same quality and brand of oil. The oil and filter must also be changed at particular time intervals. Check regularly with the engine manufacturer for procedures for draining the oil and replacing the oil filter and their disposal is to be done appropriately to avoid environmental damage or liability.

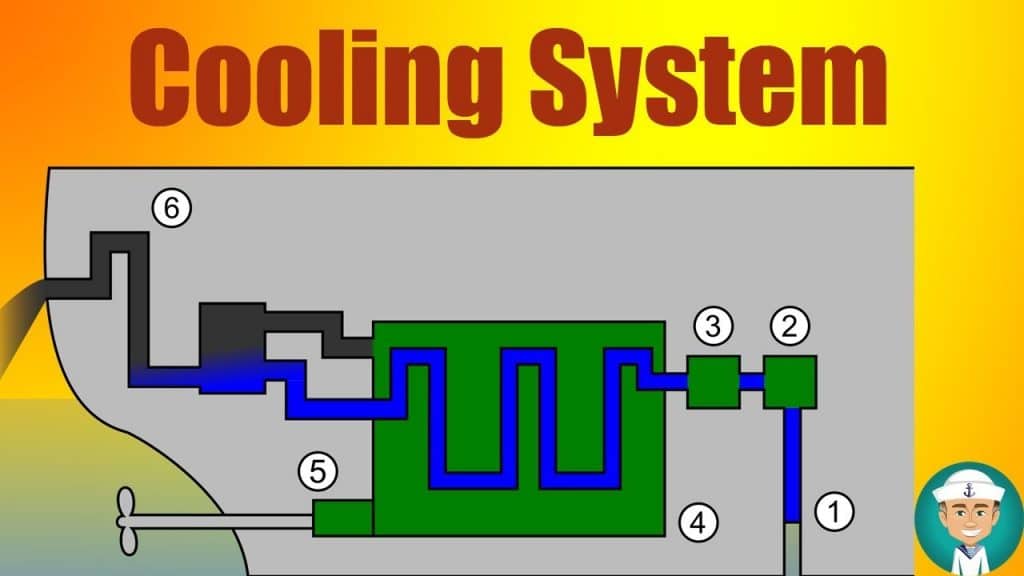

Step 2: Cooling System

Check the coolant oil level during shutdown periods at the specified interval.

Must be noted these points “remove the radiator cap after allowing the engine to cool, and, if necessary, add coolant until the level is about 3/4 in” And a More critical role in balancing diesel engines require a balanced coolant mixture of water, antifreeze, and coolant additives.

Examine the exterior of the radiator for obstructions, and remove all dirt, grimy or foreign material with a soft brush or cloth with caution to avoid damaging the fins.

If available means, use the low-pressure compressed air or a stream of water in the opposite direction of normal airflow to clean the radiator.

WARNING

Please don’t remove the pressure cap from a hot engine. Wait until the coolant temperature is below 120°F (50°C) before removing the pressure cap. Because heated coolant spray or steam can cause injury.

Step 3: Fuel System

This is the important point when it comes to the maintenance of diesel generators. Diesel is subject to contamination and corrosion within a period of time is one year, and therefore regular generator set exercise is highly recommended to use up stored fuel before it degrades.

The fuel filters should be drained at the designated intervals due to the water vapor that accumulates and condenses in the fuel tank.

Better check regularly testing and fuel polishing may be required if the fuel is not used and replaced in three to six months.

Step 4: Testing Batteries

If the battery’s charges reach the dead-end level is a common cause of standby power system failures.

The battery must be kept fully charged and well-maintained at an all-time 40% to 100% to avoid regular testing and inspection to know the current status of the battery and avoid low battery levels.

Do you want to increase battery performance?

Must be cleaned, and the specific gravity and electrolyte levels of the battery checked frequently.

- Testing batteries

- Cleaning batteries

- Checking specific gravity

- Checking electrolyte level

Step 5: Routine Engine Exercise

Regular exercising keeps the engine parts lubricated and thwarts oxidation of electrical contacts, uses up the fuel before it deteriorates, and helps to provide diesel generator maintenance to reliable engine starting.

Engine exercise is recommended to be executed 15 days once or 25 days once for a minimum of 30 min

Step 6: Keep your Diesel Generator Clean

Maintain your engine all-time nice and clean because it will be taken care of Oil drips and other issues. Check day-by-day hoses and belts that are in good condition or not.

Frequent checks can keep better conditions and other nuisances from nesting in your equipment. However, the generator users thought is a generator set that is rarely used and might not need a lot of care. So, please avoid this kind of thought and keeps regular maintenance of diesel generators based on manufacturer guidelines.

Step 7: Exhaust system inspection

In case of any leaks along the exhaust line which usually occur at the connection points, the welds, and the gaskets. Find the place of leakages and repair them immediately by a technician.

Step 8: Operating Inspections

When the Diesel Generator is Running these Guidelines Should Be inspected in operation inspection.

Common Manufacturer Inspections guidelines for diesel generators are below,

- Disconnect generator batteries.

- Drain the fuel system and change fuel filters.

- Drain coolant and change coolant filters.

- Replace air filters.

- Cover all intake and exhaust ports.

- Disconnect all generator supply connections.

So this is the important point for Diesel generator Maintenance and mainly you want to take a look at the specification of diesel generators.

If you need more details? Contact Us Today!