Shaktiman is one of the leading ELGI air compressor dealers in Chennai and all over TamilNadu. Where we supply compressors there are a lot of questions raised by the customer. So we have conducted a series Q/A among customers about air compressors. In this article, we picked out common frequently Asked Questions While Selecting Oil Free air compressor.

Top Common FAQs While Selecting Oil Free Air Compressors

1. What Are the Factors That Should Be Considered While Selecting Oil Free Air Compressors?

While selecting an oil free air compressor for your business, you should consider the following factors.

- Selecting an air compressor has a stable internal cooling temperature system because it extends the life of the electronic power components.

- Ensures the minimal loss of compressed air between compression stages are depressurized by Optimally-sized coolers.

- Will result in 4-9% more air flow per unit of power by Three-stage compression.

- Reduction in power consumption and time between load and unload by installing Titanium impellers.

2. How Is Oil Free Is Differ from Other Types?

Oil free air compressor rely on oil for lubrication. It provides the highest quality air for your manufacturing needs. All the oil free types last for 20 to 30 years.

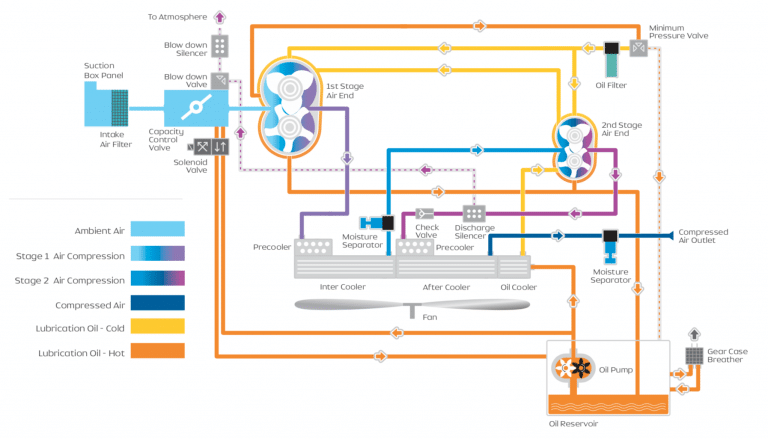

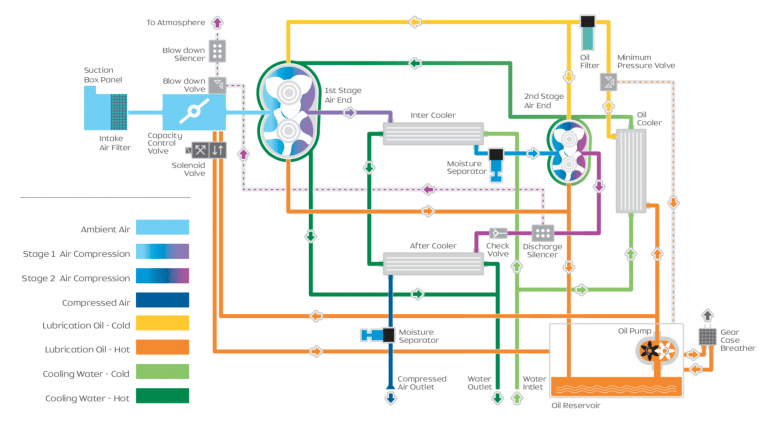

3. What Are the Different Cooling Methods Used in an Oil Free Air Compressor?

Elgi offers two types of cooling methods. They are

- Water cooled compressor cooling

- Air cooled compressor cooling

4. How Do We Choose the Right Type of Air Compressor for My Application?

Every business needs different requirements, every air compressor fulfills different requirements. In Oil Free there are High centrifugal, oil-free rotary screws & non-lubricated reciprocating compressors. It all has unique features and is designed for different purposes. The general checklist are

- What is Operating pressure?

- Does your business really need Oil-free air?

- What is the SCFM or airflow required by your pneumatic machines?

- Is your airflow demand fluctuating?

5. How Does an Oil Free Air Compressor Work?

Most oil free air compressors are using other alternative liquids to keep the mechanism smooth. Oil-free air compressors have no contact inside the compression chamber. The bearing and gears are all external and properly sealed to prevent oil contamination. It provides 100% Oil Free Air Compressors.

6. How Often Do I Need to Replace My Air Intake Filter?

Generally air filters are replaced every 2000 hrs. It is clearly mentioned in your manufacturer’ manual, In the manual they mentioned, at what condition and when your air filter should be replaced. The filters may need to change often for longer life span of air compressors.

The above mentioned questions and answers are the Frequently Asked Questions While Selecting Oil Free Air Compressors.