There are some essential Steps to Installing Air Compressor successfully. Of course, We’ll be ready to install after buying a compressor. In this phase, ensuring that the compressor is installed according to the manufacturer’s guidelines is extremely important. This ensures a long-lasting compressor, optimum efficiency, and reduces energy costs.

Where Does It Want to Be Located?

The location is the most important thing. We have to ensure that the compressor is unloaded, installed, operated, and maintained within the area during the installation. Sufficient clearance must be provided to the designated area.

However, no special foundation or anchoring is required for rotary screws of Steps to Installing Air compressor. The compressor shall be located on a high surface, which resists the compressor’s load and moving equipment.

In addition, it is necessary to protect the compressor, when eradicating the inner components, oil, and filter damage, of natural elements like rain, sunlight, hot air, and other dysfunctions such as toxic or inflammable materials and agents such as corrosion such as ammonia and chlorine, salt spray and other chemicals.

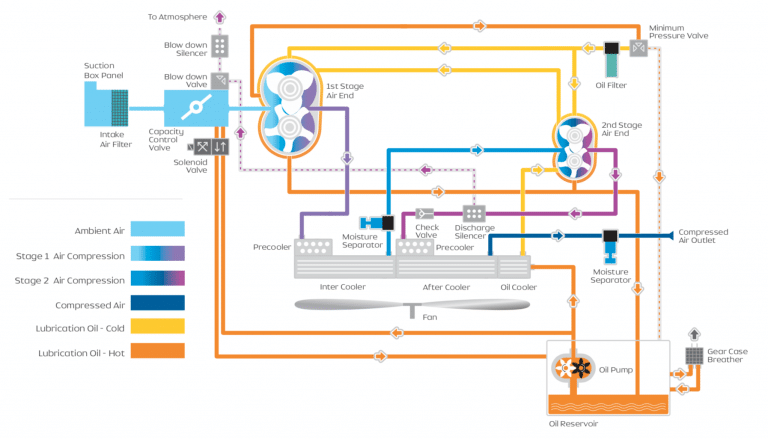

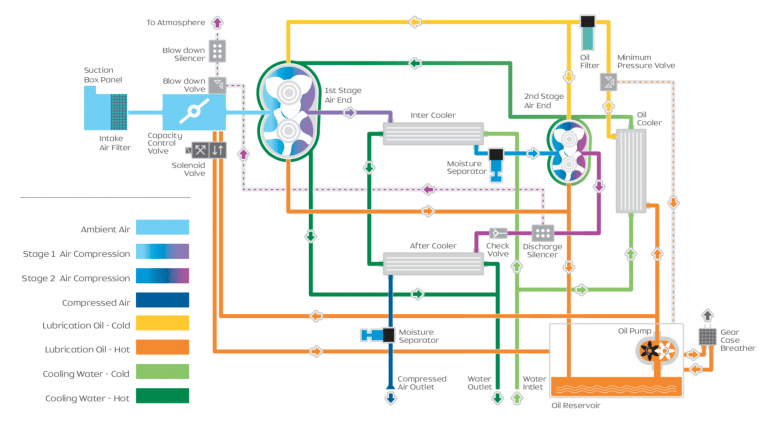

What Is the Ventilation Process and How Does It Work?

The ventilation process is the important one of the Steps to Install Air Compressors because lack of ventilation and refrigeration is the main cause of air compressor problems.

The power delivered to your compressor is fully converted into heat during compression and the heat is transferred to the compressor room.

Natural Ventilation:

When the inside compressor room temperature does not exceed 5 °C, natural ventilation is sufficient compared with the ambient temperature.

There is only a ventilation process such as

Forced Ventilation with an Exhaust Fan

If the compressor room has a maximum temperature of 5 ˚C, install an exhaust fan.

Forced Ventilation with Ducts

when it is installed in an enclosed area. Make sure that the compressor’s hot air exhaust is diverted through ducts

If the air inlet temperature falls below temperature, install a cabinet heater. To keep a temperature 0˚C – 50˚C, use the cold start kit and heater in the compression room.

How to Use Electricals That Help Maintenance?

Before the compressor is installed, ensure that the voltage of the electric service fits on the compressor nameplate (located within the electric cabinet).

The Compressor should be properly grounded & properly equipped.

Provide a dedicated switch disconnecting fusion with power to the compressor (SDF). Install a suitable SDF rating unit within five meters. This helps to maintain more than one compressor without stopping.

Air Storage

The receiver tank serves as a compressed air reservoir for maximum demand.

The receiver tank helps the water cool off the system.

The receiver tank minimizes the system pulsation due to a reciprocal compressor or downstream cyclic process.

A pressure relief valve and pressure gauge are required for the receiver tanks. The relief valve must be set to 10% higher than the system’s operating pressure.

A manual or automatic drain should also be installed in the receiver tank, to remove water.

Piping

The final Process for installing Air compressor is Piping. To provide adequate flow and steady pressure to all usage areas, the correct pipework dimension is important. The diameter of the pipe directly affects the fall in pressure. The discharge pipe must be of a minimum diameter equal to the outlet of the compressor discharge.

Piping selection affects three main components of the air system directly (flow, pressure, and air quality). Poor choice of materials in pipes, diameter, and design leads to flow restrictions and often leads to considerable decreases in pressure

Before downstream filters such as prefilters, fine filters, and carbon filters are assembled the pipelines should be flushed. Make sure the water drain for the air collector, downstream filters, and dryers is provided with the auto drain. In the event of isolation, we need to make a bypass for the dryer and downstream filter piping arrangements.

The overall system installation prevents future expenses.

Buying the new air compressor in shaktiman is the best choice because we are the best Air compressor dealers in Chennai