An Air compressor is a device that converts power from diesel, electric, and gasoline engine into potential energy stored in compressed air. Based on the pressure delivered, types of air compressors are classified.

- The Air Discharge Pressure of 150 pounds per square inch is under Low-pressure air compressors

- The air discharge pressure of 151 to 1,000 pounds per square inch under Medium-pressure air compressors

- The air discharge pressure is above 1,000 pounds per square inch under High-pressure air compressors

According to this threshold and work requirements, air compressor types are defined.

4 Most Common Types of Air Compressors and Their Uses

There are four common types of air compressors with their unique features & capabilities.

- Rotary Screw Compressors

- Reciprocating Air Compressors

- Axial Compressors

- Centrifugal Compressors

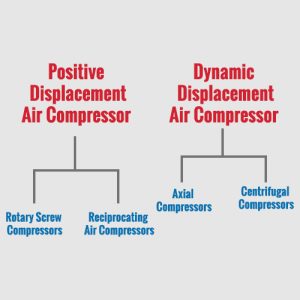

All the air compressors fall into two categories. One is Positive Displacement and another one is Dynamic Displacement.

The above 4 types of air compressors come under either Dynamic or Positive.

What Is Positive Displacement Air Compressor?

A mechanism of the Positive Displacement air compressor is to draw air into the chamber. Then the volume of this chamber decreases which will compress the air. A valve will open, and the air is then discharged into the outlet system once maximum pressure is reached. Rotary screws and reciprocating air compressors fall under this division.

What Is a Dynamic Displacement Air Compressor?

Dynamic Displacement air compressor speeds up the air to high velocity and then limits the airflow from the chamber. Because restriction in rate causes pressure to increase. Axial Compressors and Centrifugal Compressors fall under this division.

1. Rotary Screw Compressors

Rotary Screw Air Compressors are compressors that use the mechanism of rotary-type positive displacement mechanism. It mostly comes to replace piston air compressors in industrial areas. Because the industrial application needs a large amount of compressed air.

2. Reciprocating Air Compressors

A reciprocating air compressor is also the type of positive displacement compressor in which air is sucked into a chamber and compressed with the help of a reciprocating piston. There are four kinds of Reciprocating Air Compressors

- Single acting Reciprocating air compressor

- Double-acting Reciprocating air compressor

- Single-stage Reciprocating air compressor

- Double-stage Reciprocating air compressor.

3. Axial Compressors

An axial Air Compressor is an air flow-based air compressor in which airflow or gas flows parallel the axis of rotation, or axially. It converts the circumferential component of flow into pressure with the help of the stationary blades to slow the fluid.

4. Centrifugal Compressors

Sometimes Centrifugal air compressor is also called radial compressors or impeller compressors. By adding energy to the continuous flow of fluid through the impeller, high pressure is achieved.

These are the four types of air compressor and their work mechanisms. Based on the requirement of your business you can buy suitable air compressors from the right air compressor dealers.